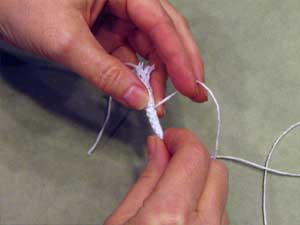

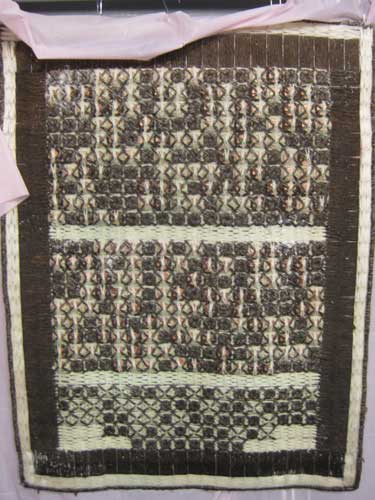

I have been trying to figure out how to age/distress wool pieces. I was pretty sure that cold wax would be the solution, but an interesting thing happened. I removed the felt that I had stitched onto the back of a piece to find casemaking moths living in a crease near the bottom.

That was it, nothing left to lose. I filled the bath with water and sodium bicarb. Tossed in the piece and left it overnight.

The next morning I applied a solution of peroxide, white vinegar, and salt.

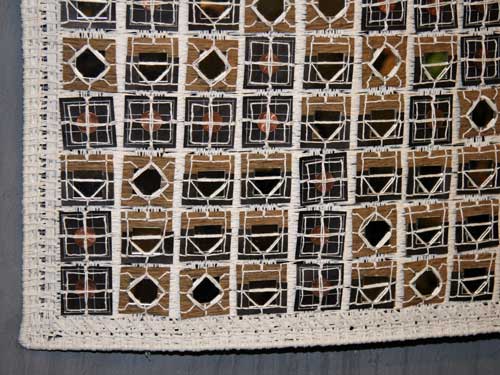

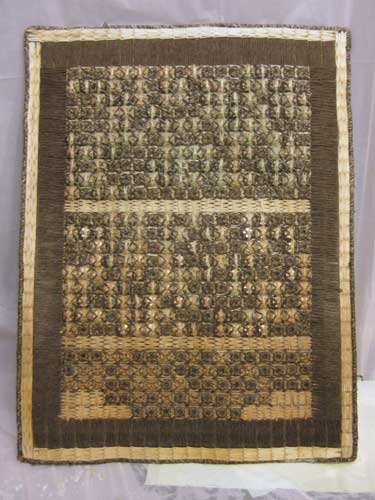

Then wrapped the piece in plastic, a bit of a brief fuming. When I unwrapped the piece sometime in the afternoon, much of the metal had oxidized. I took the piece outside and sprayed it down with the garden hose. The piece was left outside to air dry and catch some sun.

My hope is a soak overnight in salt water, saturation with a metal oxidizer, a drenching with water, and some sun would break the moth cycle.

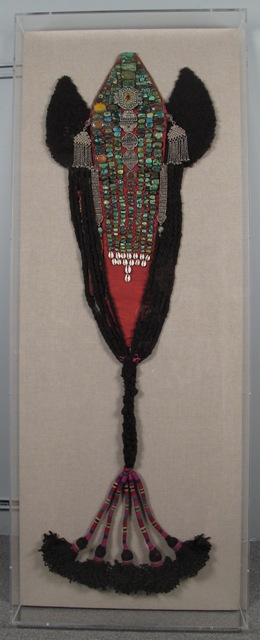

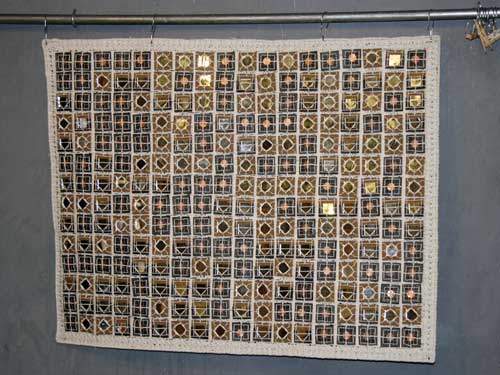

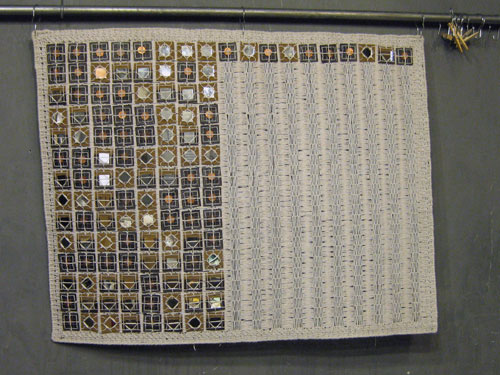

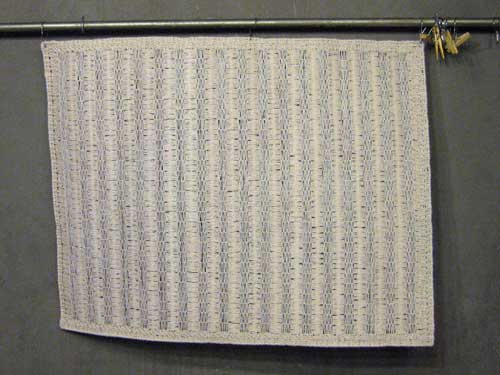

This is how the piece looks tonight.

Tomorrow I plan to give the piece an application of shellac. Yep, bug goo. I have been testing some oxides mixed with denatured alcohol, then added to shellac.

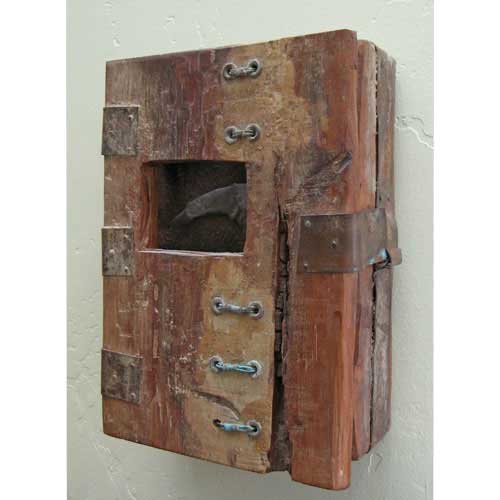

Eventually, it will be time to build a frame/box most likely out of cedar.